Contact Us

Telephone: 86-187-6548-6789

E-Mail: boss@sdktdsy.com

WhatsApp: +86-134-5573-8888

Address: Qiujiadian Industrial Park, Qiujiadian Town, Taishan District, Tai'an City, Shandong Province

Product Details

Metal pallets are important storage and transportation auxiliary equipment. The following is a detailed introduction to metal pallets:

1、 Definition and Construction

Metal pallets, also known as steel pallets, metal pallets, iron pallets, or floor slabs, are made of special profiles and are composed of panels and support legs. The main materials are steel or galvanized steel plates, which are formed by equipment, supported by various profiles, and then welded by CO2 gas shielded welding. Some metal trays may also undergo electrostatic spraying treatment on their surfaces.

2、 Type and Material

Metal pallets are mainly divided into the following types:

Iron (steel) pallets: usually made of square tubes, with excellent load-bearing capacity, commonly used in scenarios where multiple layers of stacking are required, such as the stacking of chemical, flour, and feed products.

Galvanized steel tray: The specified profiles are pressed by a dedicated molding machine and then welded manually or by welding robots. Hot dip galvanized trays have rust prevention capabilities for up to ten years, while cold dip galvanized trays may start rusting after one or two years.

Aluminum tray: It is favored by many industries due to its lightweight, especially suitable for the electronics industry, and can effectively prevent static electricity. But compared to iron pallets and galvanized steel pallets, aluminum pallets have weaker load-bearing capacity, usually around 200 kilograms.

Stainless steel tray: the most expensive among all metal trays, with a load-bearing capacity between aluminum trays and iron trays, as well as galvanized steel trays. Due to its excellent corrosion resistance and hygiene performance, it is widely used in the medical, chemical, and food industries.

3、 Characteristics and advantages

Strong load-bearing capacity: The metal tray is made of metal materials such as steel, which has a high load-bearing capacity and can meet the handling needs of various goods.

Good durability: Metal trays have good wear and corrosion resistance, a long service life, and reduce the cost of frequent tray replacement.

Good stability: The structure of the metal tray is stable and not easily deformed, ensuring stable placement of goods during transportation.

Convenient for mechanized operation: The surface of the metal tray is flat, making it easy for forklifts and other handling equipment to grip smoothly, thereby improving the efficiency of mechanized operation.

High safety: Metal pallets have certain anti slip performance, effectively reducing cargo damage and safety accidents caused by slippage.

Strong adaptability: Metal trays can be customized with different sizes, shapes, and load-bearing capacities according to different scenarios and needs.

Easy to clean: The surface of the metal tray is smooth and easy to clean, which can effectively prevent problems such as cargo contamination and virus transmission.

Recyclable: Metal pallets can be recycled to reduce resource waste and environmental pollution, in line with the concept of sustainable development.

4、 Application scenarios

Metal trays are widely used in various fields, including:

Manufacturing industry: Metal pallets can ensure stable transportation of materials during material handling, component assembly, and other processes on the production line.

Logistics warehousing: The storage and handling of goods in the warehouse, with metal pallets, can improve the utilization of warehouse space and increase handling efficiency.

Retail industry: In retail venues such as supermarkets and stores, metal pallets can be used for the placement and handling of goods, improving the display effect of products.

Catering industry: Metal trays can be used for the transportation and placement of food, beverages, and other items, making them easy to clean and disinfect.

Pharmaceutical industry: Metal trays can be used for the handling and storage of sensitive products such as drugs and medical devices, ensuring product safety.

Chemical industry: Metal pallets can be used for the transportation of toxic, harmful, and easily leaking chemical products to improve safety performance.

5、 Precautions

Although metal trays have many advantages, the following points should also be noted during use:

Avoid overloading: The weight of the goods should be arranged reasonably according to the carrying capacity of the metal pallet to avoid overloading causing deformation or damage to the pallet.

Regular maintenance: Regularly inspect and maintain the metal tray, such as checking whether the welding parts are firm and whether the connectors are loose, to ensure the safe use of the tray.

Correct operation: When using forklifts and other handling equipment, ensure smooth and slow operation to avoid impact or damage to metal pallets.

In summary, metal pallets play an important role in the modern logistics industry due to their superior performance and wide range of applications.

You have not found a satisfactory product, please rest assured that we provide customized services.

We have superior customization capabilities to tailor products to your needs.

We believe that communication can inspire new ideas and look forward to working with you for a better future.

Please feel free to contact us.

Previous

Next

Previous

Previous

I want to make an inquiry

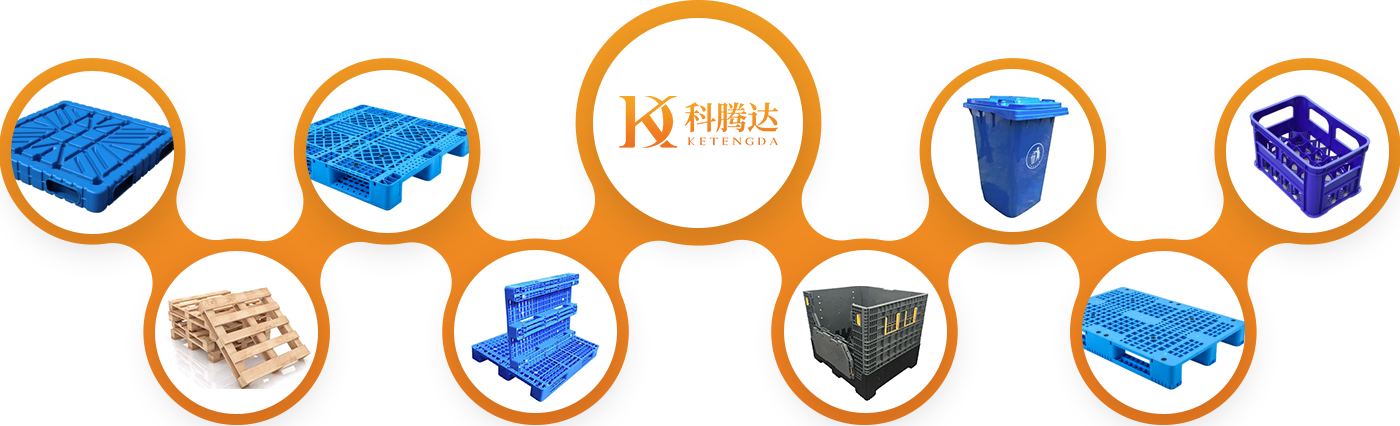

Series Products